Many of us are familiar with the term relative humidity by looking at the weather report. Relative humidity is the amount of water vapor expressed as a percentage of the total that the atmosphere can have at a given temperature. The higher the temperature, the greater the amount of vapor it can hold.

In steam autoclave sterilization steam purity, steam saturation and availability are important process variables. The purity of the steam is the quality of the steam or saturation. This refers to the amount of moisture contained in the steam.

Steam quality is measured in terms of the presence of water as a supersaturated mixture. Current standards suggest a steam quality greater than 97% (97% to 100%), this means that the steam used to sterilize must contain less than 3 % of liquid water.

If there is an excess or deficit of water inside the sterilizer, the characteristics of the steam will not be optimal, this decreases the efficiency in heat transfer and therefore can generate failures in the sterilization process.

In order to obtain efficient results during the sterilization process, the equipment must generate saturated steam, saturated steam is similar to air with 100% relative humidity.

Saturated steam fulfills an important property on which the principle of moist heat sterilization is based; the pressure exerted by the saturated steam is constant for a certain temperature and will vary in direct relation to that temperature; that is, the higher the pressure, the higher the temperature and vice versa. Likewise, if there is an excess of water contained in the steam or if the saturated steam is abruptly cooled, the water will condense and turn into liquid, which affects the packaging. Wet packages or containers are potentially prone to problems since different microorganisms can use the liquid medium as a vehicle to contaminate the contained materials,

The IVDU integrator measures the quality and quantity of steam received during sterilization and is related to time, temperature and steam purity.

In the presence of excess water, the IVDU integrator denatures and loses its shape – it is diluted – indicating failures in the quality of the saturated steam and alerting the user to a potential problem in the sterilization process (in the presence of water it does not fulfill the function of integrator for sterilization).

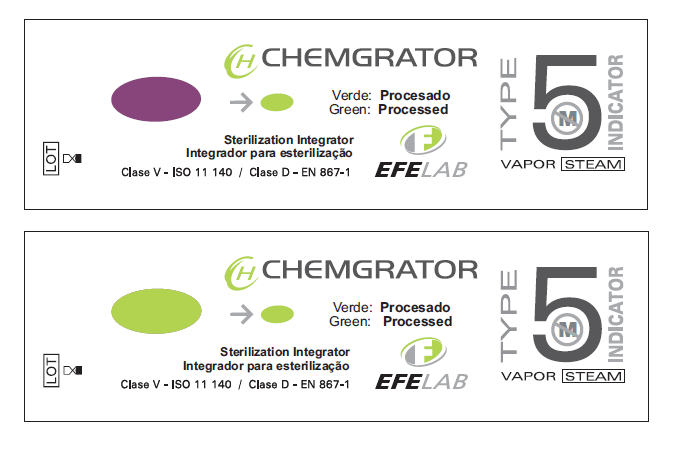

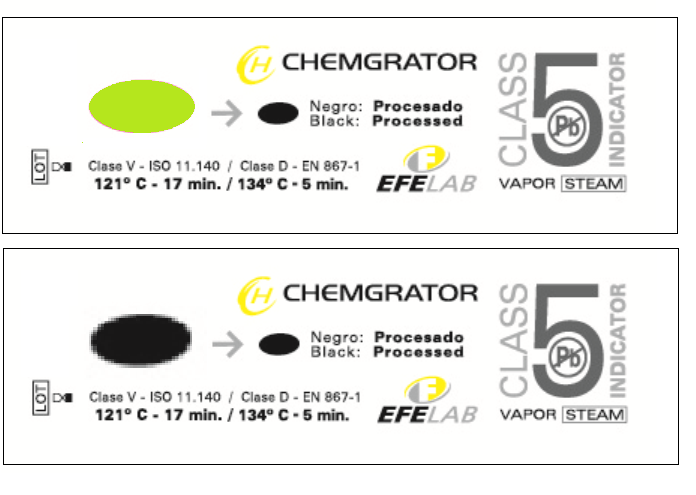

CHEMGRATOR indicators are specially designed to integrate the effects of time, temperature and steam quality in a sterilization processes. The color change of the integrator only occurs in the presence of these three conditions, thus providing immediate visual evidence if the necessary sterilization conditions were reached during the cycle. This can be noticed by the change of color of the indicator ink to its reference color.

- Indicator ink developed to change its color when a theoretical population of 10.6 spores of Geobacillus stearothermophilus bacteria reaches its point of death, indicating that the indicator integration condition was reached.

- The integration condition has been calculated in a BIER device (Biological Indicator Evaluator Resistometer).

- High-quality indicator that meets the requirements of ISO 11140-1 Class or Type 5 and IRAM-37101-1 standards).

- The integrator changes from purple to green and the initial and final colors have been printed on each integrator for an immediate interpretation of the cycle results.

- The color change is irreversible, and can be used as a record of the sterilization cycle.

- Use this product to verify steam sterilization cycles between 121 ° C and 135 ° C.

- The integration condition is reached in steam sterilization processes as indicated in the quality certificate.

- 100% heavy metal free product.

- Product Shelf-life: 60 months from the date of manufacture.

.

Main features of Chemgrator integrators

- Easy reading and interpretation.

- Results available immediately after performing a sterilization cycle.

- Practical and easy to use.

- Reliable.

- Do not require laboratory culture.

- High-quality: meets the requirements of ISO 11140 Type 5 standards.

| PRODUCT CODE | CLASS | PROCESS | TIME | TEMPERATURE |

| IVDU | V | Steam | (Integration Condition) | From 121ºC to 135°C |