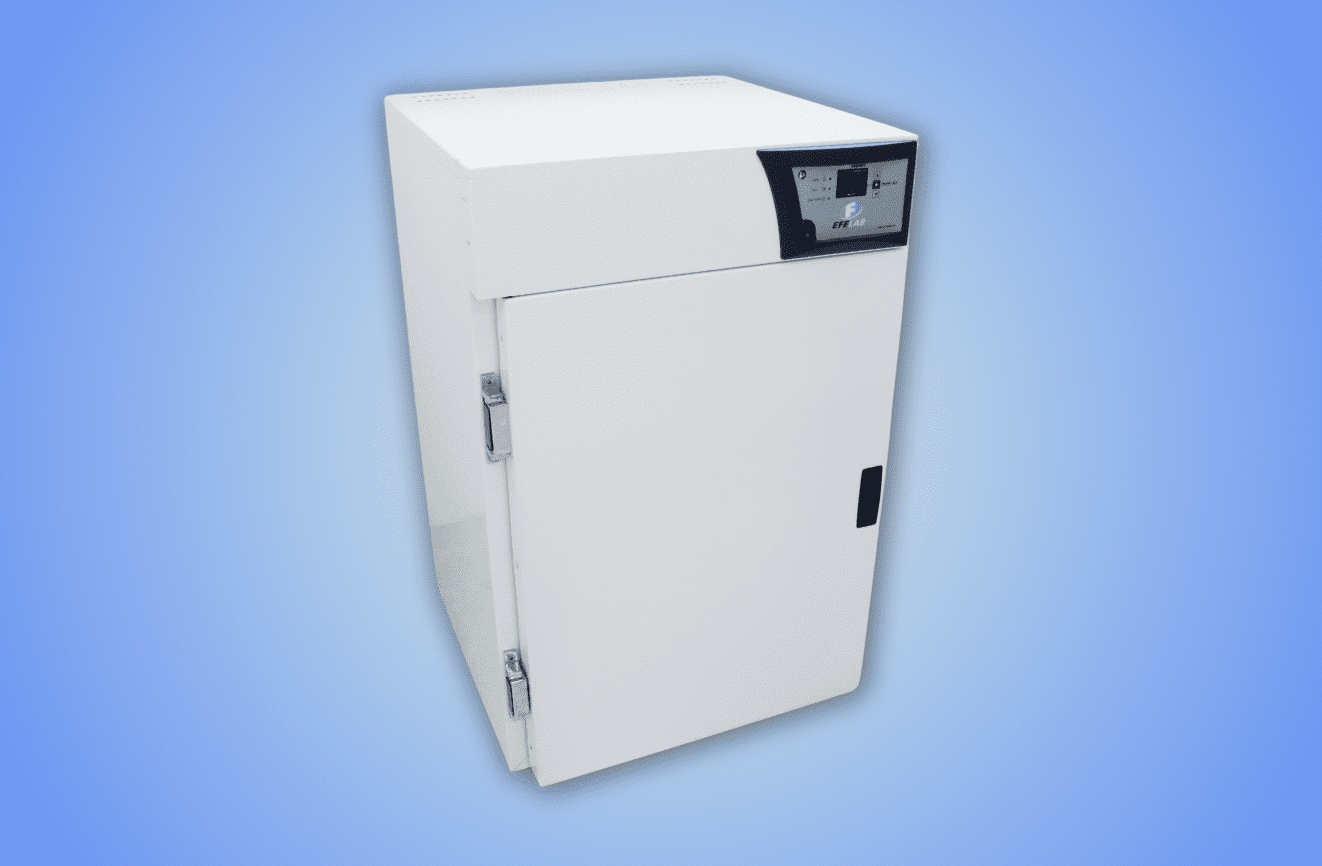

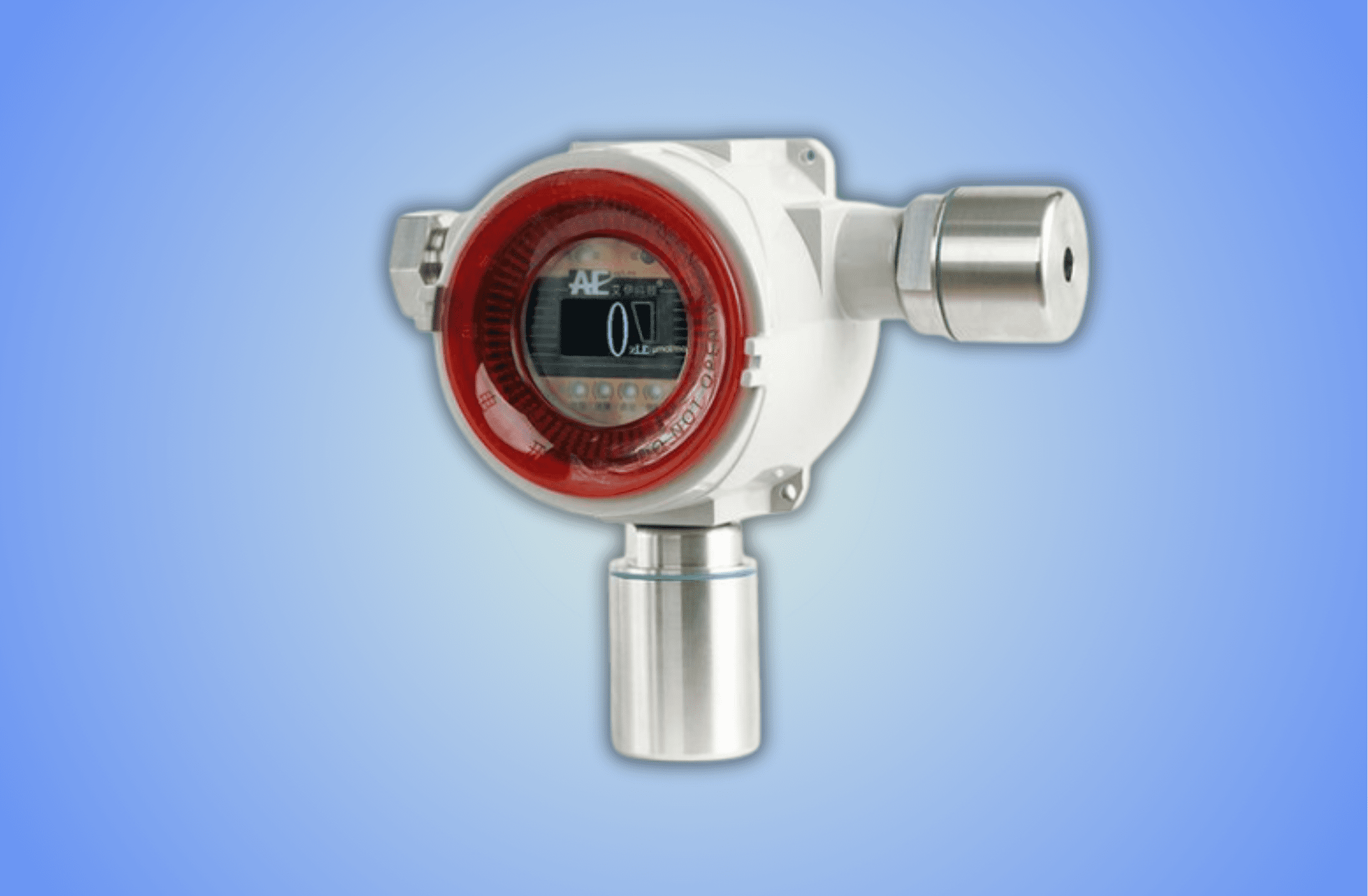

AIR96 – ETO Ventilation & Conditioning System

The AIR96 Ventilation System has been developed to ensure a safe and efficient sterilization process with ETO. Designed to condition and ventilate sterilized materials, this system allows precise control of critical variables such as time, temperature, and purge, ensuring optimal conditions according to the user’s needs.

What is the AIR96 system?

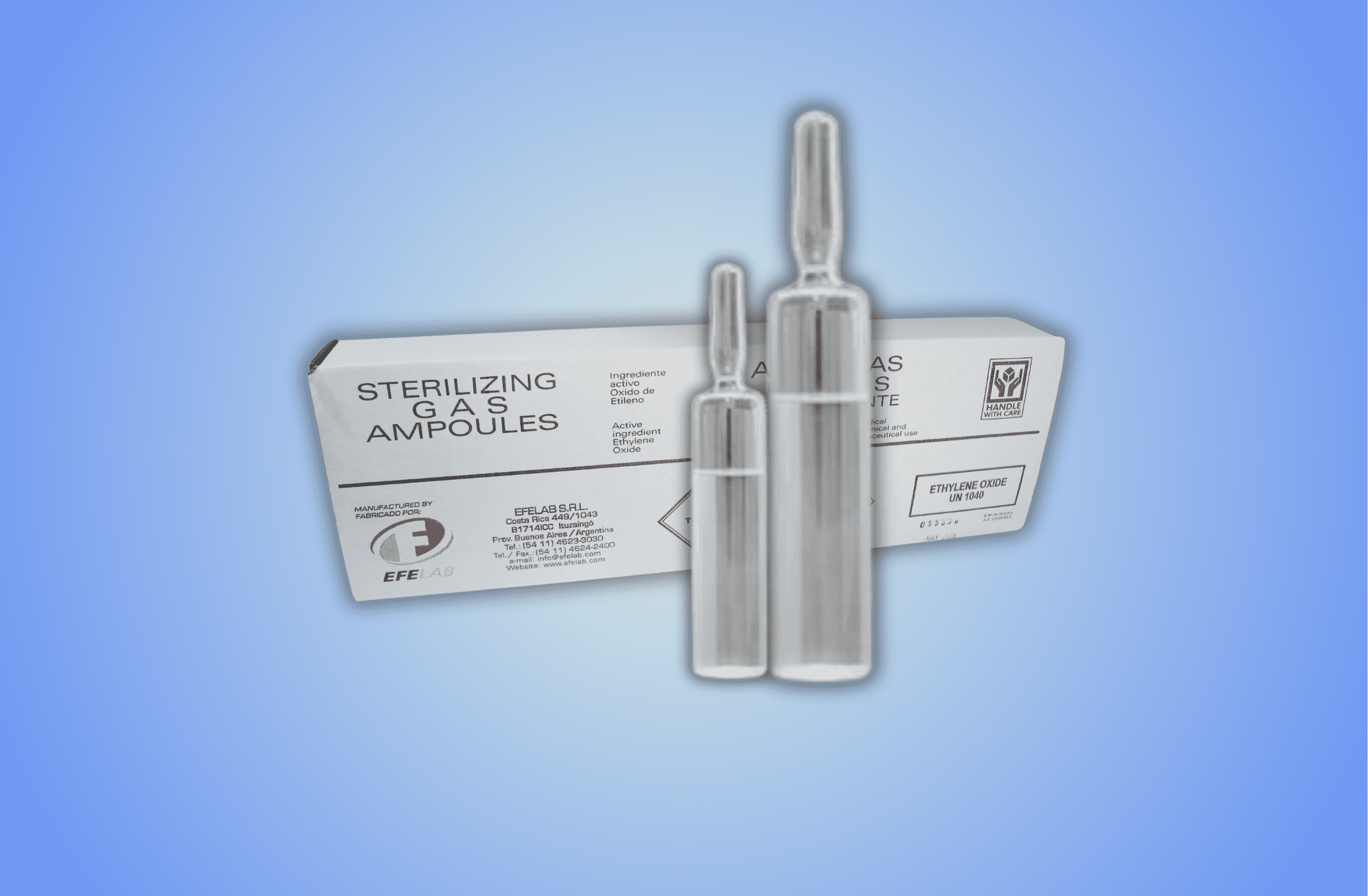

The AIR96 is a ventilation system for ethylene oxide that enables the post-sterilization treatment of materials exposed to ETO gas. It is a safe, robust, and efficient solution that complies with current regulations and protects both the operator and the environment.

Main features of the AIR96 ventilation system

✔ Optimized capacity: 96-liter chamber designed for use with 34-liter bags.

✔ Hermetic sealing: Ensures a controlled environment and prevents gas leaks.

✔ Intuitive interface: Allows programming and adjustment of time, temperature, and purge according to user requirements.

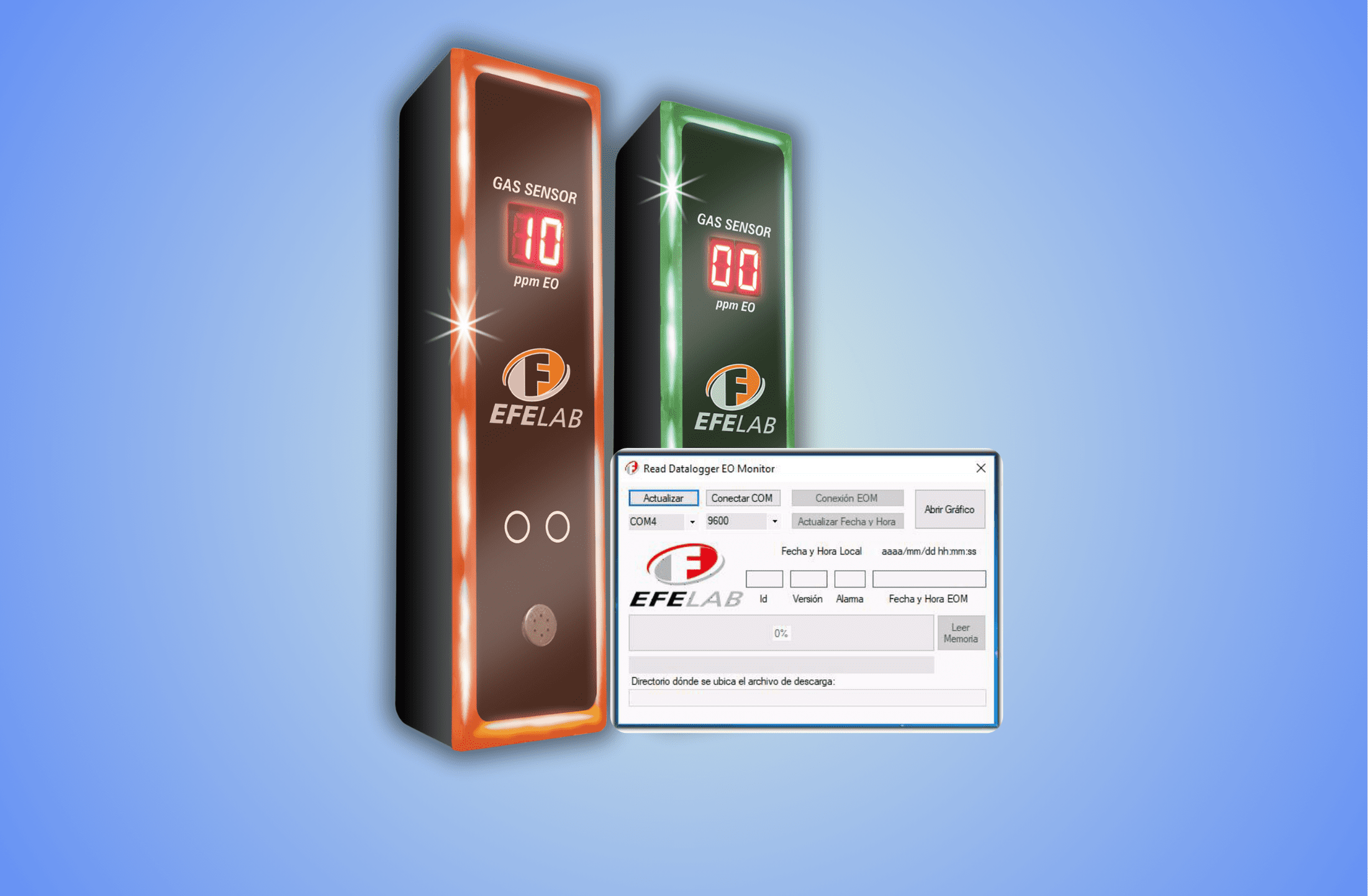

✔ Safe disposal: Ventilation system designed for efficient evacuation of residual gas.

Why choose a ventilation system for ethylene oxide?

Using a dedicated system such as AIR96 effectively controls the presence of gaseous residues in sterilized materials. This guarantees greater safety in the work environment, improves process quality, and complies with international standards such as ISO 11135.

Compatibility and documentation

The AIR96 is compatible with any type of ETO-sterilized material requiring a conditioning or controlled ventilation phase. It comes with:

- Product brochure

- Safety data sheet

- Instructions for use (IFU)

- ETO emergency card

Request more information

For detailed technical information and usage recommendations, please refer to the product brochure or contact our specialists.