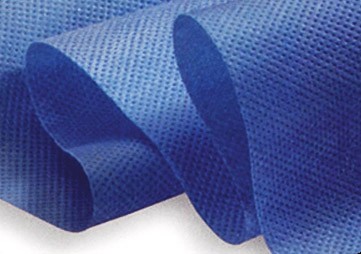

About the production of medical grade paper:

The cellulose used in the manufacture of medical grade paper is usually obtained from the wood of trees originating in Nordic countries. This is because in these countries there is a constant presence of snow and cold temperatures that make the growth of the tree slower and more progressive, forming a characteristic type of fiber especially resistant. Low temperatures also prevent the proliferation of pests, eliminate the need for fumigation and the use of chemicals, also resulting in greater purity of the material. This cellulose does not receive any type of chemical treatment, with it the fibers are manufactured with exactly the same degree of purity as when extracted from trees. Once the production process of the cellulose fibers begins, different measures are taken to produce more long fibers than short ones, since the long fibers are those that make up more than half of the medical grade paper structure. When manufacturing medical grade paper with pure cellulose no optical brighteners are used.

The cellulose fibers are bonded using a special glue-based adhesive, which in addition to maintaining the degree of purity, allows the medical grade paper that is obtained to resist moisture, an important characteristic when subjected to the process of sterilization by moist heat. Medical grade sterilization papers are an effective barrier against the penetration of microorganisms and environmental dust, they are permeable to the sterilizing agent while their reduced pore size guarantees safe storage properties. They have resistance to both dry and wet handling and to the sterilization method used, they do not release material during use and do not damage the material packed in it. They have high mechanical strength in both dry and wet conditions, and are compatible with sterilization processes by steam, ethylene oxide and gamma rays.

Our Medical Grade Paper, meets rigorous international quality standards: EN 868 -2, EN 868-3 , EN 868-6 AND ISO 11607.

Main characteristics of medical grade paper:

- Manufactured with pure cellulose.

- Controlled porosity in 0.1 microns.

- It does not have optical brighteners.

- Its structure withstands great pressures during the sterilization process.

- Resistant to humidity (compatible with steam sterilization process).

- It has at least 55% long fibers.

- Avoid or reduce breakage during the sterilization process.

- Represents an effective barrier against microorganisms.

- It is permeable to the sterilizing agent.

- Presentation: Reels and reams of several sizes.